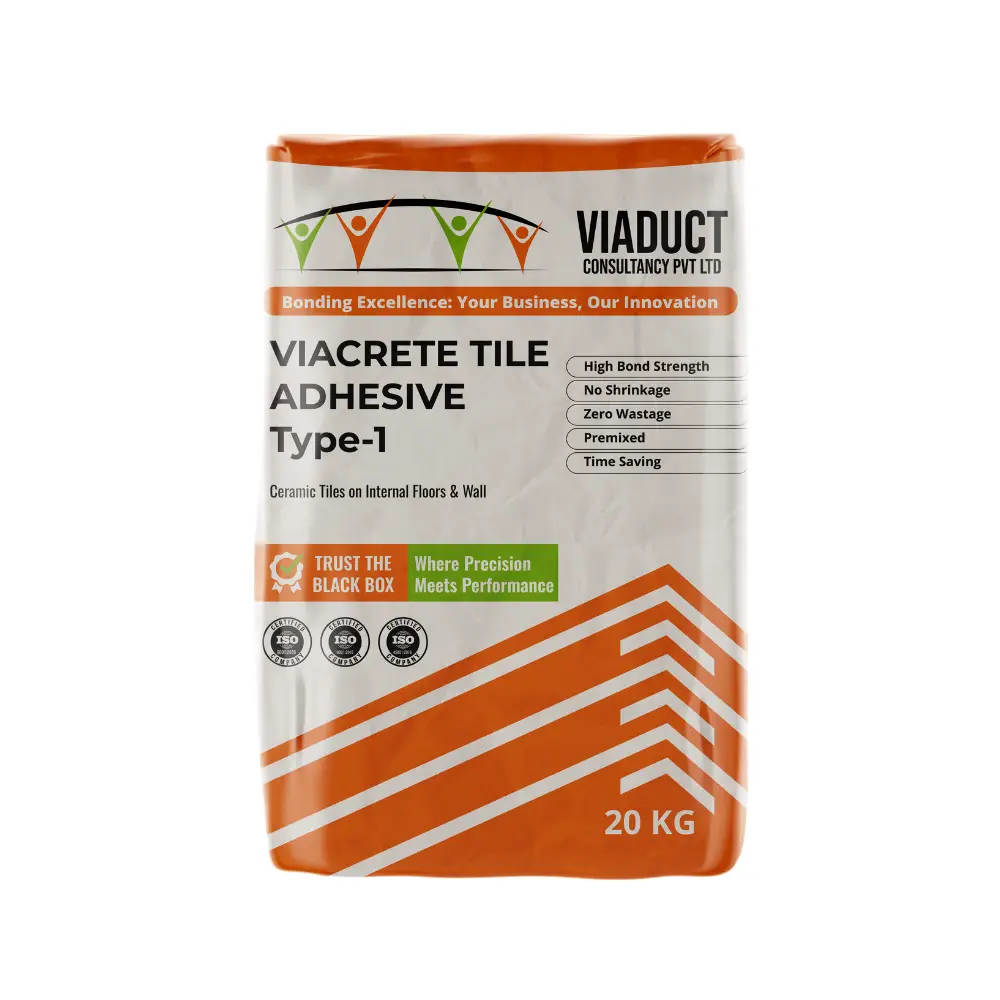

Viaduct Blackbox for Tile Adhesive (Type 2 – Grey/White)

Quick Specifications

Packaging Units:

20 /40 KG

Packaging Type:

Powder

Colors:

Grey/ White

Key Features

Zero R&D Investment

Move directly into production without spending time, money, or manpower on formulation trials or lab development.

Faster Market Entry

Launch a high-quality Tile Adhesive Type 2 within days, not months, giving you a strong competitive edge.

Guaranteed Batch Consistency

Every batch performs the same, thanks to a validated recipe and controlled polymer system that eliminates formulation guesswork.

Reduced Raw Material Complexity

One smart polymer system replaces multiple additives, simplifying procurement, storage, and inventory management.

Higher Production Efficiency

Clear mixing ratios and streamlined processes enable faster manufacturing cycles with minimal supervision.

Compliance Without Effort

Achieve EN 12004 (C1) and IS 15477 (Type 2) standards effortlessly through a formulation that’s already engineered for compliance.

Stronger Market Positioning

Deliver a premium adhesive with superior adhesion and workability, building trust with distributors, contractors, and end users.

Cost-Optimised Manufacturing

Efficient polymer performance enhances coverage and strength, improving margin potential for manufacturers.

Scalable Production

Whether you're producing small batches or expanding to high-output manufacturing, the formulation scales seamlessly.

Minimal Skill Dependency

A simplified formulation process means you don’t require highly skilled chemists to maintain product quality.

Complete Technical Support in One Box

From recipe to QC parameters, everything needed for smooth production is already included.

Lower Risk, Higher Reliability

A proven, controlled system reduces production errors, customer complaints, and product failures, protecting your brand reputation.

Technical Specifications

Detailed technical specifications and performance characteristics of AAC Block – Ultra Light

Parameters

Results

Colour

Grey/White Powder

Mixing Ratio (Powder : Water)

3.5 : 1

Bulk Density

1.3 – 1.5 gm/cc

Mixing Density

1.7 – 1.9 gm/cc

Pot Life

2 Hours (Provides a comfortable working window without premature hardening)

Open Time

~ 20 Minutes (Ensures adequate time for tile placement and alignment)

Adjustability Time

~ 20 Minutes (Ensures adequate time for tile placement and alignment)

Final Setting Time

24 Hours

Coverage (20 Kg Bag)

55-60 Sq. Ft. @3mm bed thickness

Maximum Bed Thickness

15 mm

Time to Light Foot Traffic

16 – 24 Hours (Suitable for fast-track internal applications)

Ready for Grouting

24 Hours

Ready for Use

14 Days (Ensures complete curing and long-term strength)

Property

Value

Standard

Density

550 kg/m³

IS 2185 Part-3

Compressive Strength

4.0 N/mm²

IS 2185 Part-3

Dry Density

451-550 kg/m³

IS 2185 Part-3

Thermal Conductivity

IS 3346

IS 3346

Fire Resistance

4 hours

IS 3809

Water Absorption

10% by weight

IS 2185 Part-3

Drying Shrinkage

0.04%

IS 2185 Part-3

Modulus of Elasticity

2400 N/mm²

IS 2185 Part-3

How to Use Viaduct Blackbox in Manufacturing

Prepare Your Mixing Equipment

Ensure the mixer (ribbon, plough, or high-speed blender) is clean, dry, and free from previous batch residues.

Measure the Required Raw Materials

Weigh cement, fillers, and additives as per the prescribed formulation included in the Blackbox technical sheet.

Open the Blackbox Polymer System

Carefully open the sealed Blackbox and confirm that the material is moisture-free and ready for use.

Add the Polymer to Dry Materials

Introduce the Blackbox polymer into the mixer along with the pre-weighed raw materials in the recommended ratio.

Begin Dry Mixing

Start the mixer and allow the materials to blend uniformly for the time specified in the formulation guide to ensure even dispersion.

Perform Mixing Consistency Check

Stop the mixer briefly and visually inspect texture, colour uniformity, and flow characteristics as per QC guidelines.

Complete the Final Blend

Run the mixer for the remaining prescribed time to achieve a fully homogeneous Tile Adhesive Type 2 powder.

Conduct QC Verification

Check bulk density, mixing density, flow, retention, and basic adhesion benchmarks to ensure the batch meets Type 2 specifications.

Pack and Seal the Finished Adhesive

Fill the adhesive into 20kg or custom-labelled bags, seal them properly, and store them in dry, well-ventilated conditions ready for dispatch.

Frequently Asked Questions

Get answers to common questions about AAC blocks, construction techniques, and project requirements

Related Products

Explore our complete range of construction materials and solutions that complement AAC blocks for your building projects

Industry Knowledge Hub

Still Have Questions?

Our technical experts are here to help with your specific project requirements and questions.